“S.V.K” Ltd. is the

Russian company

specializing in dispersion techniques since 1995. In cooperation with “Ateliers Sussmeyer” S.A. (Belgium) we introduced horizontal supermills HM EHP to the

Russian market and other countries (Ukraine, Kazahstan and Belorussia).

The process is to grind filmforming materials with grinding media (glass beads, zirconium oxides or metal beads). Initially, till 1999, we manufactured the mills by the original drawings and in cooperation with “Ateliers Sussmeyer”, till the company stopped it`s activity. As the years went by we were invited to assist in dispersion problems of widely diverse industries. This resulted in the modification of our machines to accommodate not only film forming materials but also dispersions such as magnetic tapes, sensitized papers, confectionery, paper slurries, latex intermediates, etñ. Each required special and individual research into techniques and media to be used. Our equipment is completely versatile and can be used without modification to grind any form of grinding media currently available.

The main products for which our horizontal mills may be used are:

- high quality finishes and ordinary enamels, with synthetic, nitro-cellulose or natural binders

-

additive dispersions for lubricants

-

additive dispersions for lubricants

- photographic emulsions

- pharmaceutical dispersions

- primers and surfaces

- cosmetics

- ordinary oil paints

- wax and plastics inks for carbon paper and typewriter ribbon

- rust inhibiters

- wash primers

- adhesives

- emulsion paints

- printing inks

- cocoa

- pigment manufacture

- herbicides and fungicides

- dyes and fillers for textile fibers, leather, etc.

- dispersions for paper industry

- sensitized paper coatings and etc.

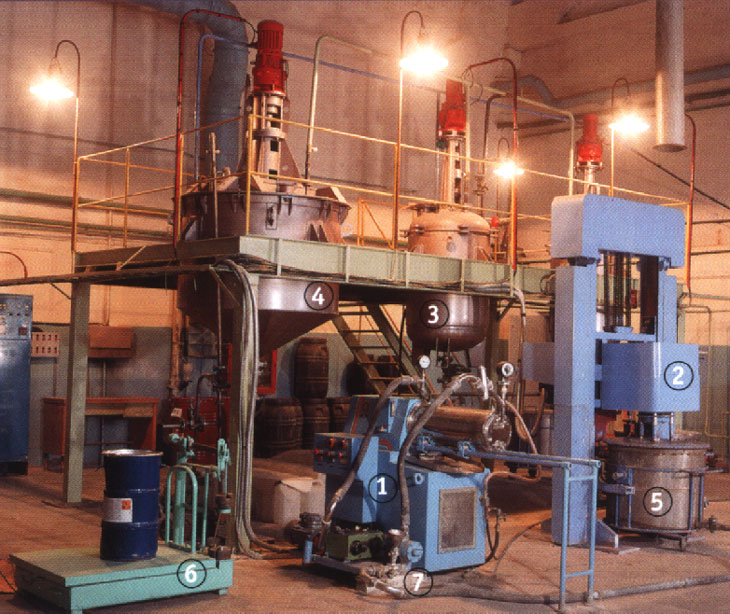

The mill base, consisting of pigment, vehicle, solvent and (if necessary) extenders, should be premixed before being pumped into to à mill. Our company is producing a full range of dissolvers (stationary or with movable vessels of different volumes) for pre-mixing, mixing, dispersing and dissolving with increased output due to rotation speed control systems which give optimum results with medium and high viscosity products.

All other equipment, including filters, mixers, stain less steel vessels (with jackets for heating and cooling of the product) and etc. is manufacturing by our company, which gives a customer the possibility to receive the full range of service by a “key-turn” contract.

Our company is producing the equipment in various construction variants, depending on the Customer’s requirements. To achieve an even better adaptation to the special conditions of the mixing vessels used, intermediate sizes deviating from the standard designs can be produced at a notice.

For our Customers we have made our service preparedness and spare parts availability à principle of our company!

You are invited to join the number of our Customers!